saxxon

Members-

Posts

23 -

Joined

-

Last visited

About saxxon

- Birthday 12/12/1968

OCC

-

Computer Specs

The specs are:

Saxon Computers Hemmed LCD Case with Keyboard Slide

GIGABYTE GA-965QM-DS2 LGA Q965 Express Micro ATX Intel Motherboard

eVGA GeForce 8800GTS 320MB Superclocked PCI Express Video Card

Western Digital Raptor X WD150GB 10,000 RPM Serial ATA150 Hard Drive

HIPER HPU-4B580 12V v2.2 580W Power Supply

OCZ Platinum 2GB (2 x 1GB) 240-Pin DDR2 SDRAM DDR2 1066 (PC2 8500)

Intel Core 2 Duo E6700 (loaner chip employee benefit)

ViewSonic's 20.1" VX2025wm widescreen LCD

HIPER HCK-1S18- Silver Slim Clavier Keyboard

Sony NEC Optiarc 18X DVDSATA Model AWG170S-B2

AeroCool TURBINE 1000 120mm Fan

LINKSYS WRT54GL Wireless-G Broadband Router

HAWKING HWUG1 USB 2.0 Wireless-G Adapter with Removable Antenna

ALTEC LANSING Speakers

Logitech 931379-0403 Cordless Notebook Mouse

Profile Information

-

Location

oregon

-

Interests

electronics, biking, guitars, cooking

Contact Methods

-

Yahoo

[email protected], jasgato@yah

- Website URL

-

ICQ

0

saxxon's Achievements

Newbie (1/14)

-

Aluminum honeycomb avaliable at FrozenCPU.com

saxxon replied to saxxon's topic in Overclocking and Cooling

Nice to see your post kingdingeling, I like the FrozenCPU pics that you can zoom so large. They are also carrying the material only as a low cost alternative. http://www.frozencpu.com/products/7099/ffa...ut_Housing.html -

The folks at FrozenCPU.com started carrying Honeycomb Flow Straighteners. They were impressed by their performance. If anyone from this site purchases one please post pictures and some results data: http://www.frozencpu.com/products/7096/ffa...mm_Housing.html

-

These honeycomb products are intended for case fans and not really CPU fans. But that sure does not stop people from trying them on the CPU. CPU fans are pretty low RPM. And you do have to have the proper spacing for a CPU. That will add considerable flow in the center dead spot. For case fans they stop the flow from dissipating so quickly as kingdingeling described. "I've always wondered whether this guy got his idea from modders mesh?" I wish anything came to me that easily. To ensure I had quiet and efficient cooling on my case (photos at saxxon.net )I read for days about fluid dynamics. Then I read this page from Stanford windtunnel honeycomb and still I did not piece it together until I made one out of drinking straws plastic honeycomb That plastic handmade one I strapped to a 120mm fan after blowing through it. I was quite shocked at that point. I am not sure how long aluminum honeycomb has been around, it is mostly used for aerospace sub-flooring and panel spacing. And it is quite difficult to get in small quantity. Here is my best results using honeycomb on a CPU fan. It was running a stable 20C with the honcycomb on the CPU fan, then I removed the honeycomb and with fan only it climbs to 33C. That was a Pentium 805D with stock heatsink. Higher end heatsinks with downdraft instead of side draft seem to work better with honeycomb attached. As a fanless intake application I took this photo of smoke going through the case. This was still experimental when I completed this case, but it has proven to be work quite well cooling all the hardware and keeping the PC hardware heat from mixing with the LCD heat. clear top with smoke Thanks for posting some results kingdingeling. Let me know any more details you come up with.

-

Smack all Over with Intel's Smackover

saxxon replied to road-runner's topic in Processors, Motherboards and Memory

all 12 people, too funny! -

Smack all Over with Intel's Smackover

saxxon replied to road-runner's topic in Processors, Motherboards and Memory

I will have to ask about the ICH10R chipset. I have not even heard that it has taped out yet. I work at F20, the Intel P861 network, making the ICH9, but have not seen any lots of ICH10 come through yet. It is either being made in MA or a P1260 process. I will find out. It is great that Intel finally admits there is gamers out there. -

This is starting to look like it's going to be a good review allready Bleeble. Good reference to your test methods and photos. Make sure you can post most your hardware specs too. I found a good pic of an EMI shield too. Here is an EMI shield for an aircraft, looks pretty much the same, but these are expensive parts.

-

Nice, someone who uses 80mm 3-4 sheets are not too much, and I can cut it to 80mm for you if you want just the material with no housing. It is fun material to test with. This one has run since june in this system, helping the NB and memory temps. And noticably less dust build up on the hardware than the stock fan was leaving.

-

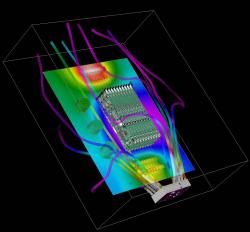

Well I didn't mean to make it that obvious. And I didn't want to post on here and make it overkill. Wow, your the first group who has wanted to make one out of drinking straws. It took me a few hours to put that one together. But it worked so well I made 2 more 80mm's, one ran in my other system 3 months. I will post a few independent reviews on here for you folks. yoshi02, I appreciate your interest, this should help you make an informed decision. What size were you interested in? Seems like high performance systems long ago outgrew the 80-92 mm sizes, most interest is for 120mm. Bleeble is the only OCC member I know for sure has these, and he is working on a review. He was interested in using them for a watercooling radiator. I inquired about a review from OCC but The engineer that called me from Analogic said he was skeptical and got up into the light fixture in the building to see for himself. Industrial buildings use a 1/4 inch square lattice to aim the lighting, so he broke out a piece of this stuff and tried it out. What was funny was he said "I can't just take all the light fixtures out of the building, so I called you" I don't even know where all these industrial engineers get my information, unless they are reading Ebay or OCC, PCApex and the like. But I get more industrial orders and inquiries than PC fans. Especially in the U.S., but hey, I am the same way. If I don't see it in Tom's Hardware or Fox News I don't believe. Probably the best review I have recieved was from Analogic, they were running 4 120mm straighteners in the rotating gantry of a CAT scanner to cool 10 tightly packed video boards. Here is an Analogic CAT scanner: And this is a CFD image of the CAT video boards from daat.com The feedback I recieved from them was: Roby Prentiss- ME- Analogic Corp. 120mm running in CAT scan rotating gantry "These flow straighteners worked too well. If these were designed into the product in the beginning it may have worked better than trying to use them as a "fix" in the end. The straighteners got allot of attention by many of our project engineers who witnessed a dramatic performance increase. With this knowlege I suspect in the future these devices may be coupled with smaller less expensive fans. thank you for all your help" Getting good results from my CPU temps, frame rates and such was great but improving a million dollar CAT scanners performance was better validation than I could produce. Many universities and businesses do not bother with writing a review Here is the only online review so far, from the UK at voidedwarranty.com Voided Warranty Honeycomb Review And that is using plastic industrial manufactured straws. The aluminum honeycomb works much better. PCApex has done a review but is has not been posted yet. It usually takes a while. Here are some personal reviews: The Slayer (Hardware Hell forum moderator) Intel Core 2 Xtreme 6800 2-xfx 7950 GX2's Corsair PC2 8500 "..with Silverstone FM121 fan I was 3 degrees C cooler at idle and load." "My GeminII heatsink will have some of these as a permanent fixture" Ratchetfps (PC Apex forum) "makes any fan into a bad a ss fan" Rick Dudley (Gamer) "P4 Prescott has never run cooler, running only with side case fan 80mm honeycomb" Barry Sharp (Intel F20 technician) Installed on TEI 120mm AC 110 fan Model TA1238-M-110 for Onkyo Home Theater Receiver - TXNR901B "Before adding a fan to my media cabinet the receiver would overheat and shut off. Adding the fan helped but I could turn down the speed for improved cooling and lower noise when I added the air flow straightener. Receiver running full power is now cool to touch and has never shut off. Thanks for the help Saxon PC. (P.S. I also used this same design at my office where my pc is in an enclosed cabinet and now stays much much cooler." Fungi (Silent PC Review forum) "straightener put an "invisible duct" over 3 feet away, surprising how focused the air became at that distance. It might be useful for spot coolers that have to blow on something a little ways away." Here is a photo of the big panels used in wind tunnels: The north bridge in my clear acrylic case ran hot, George Forman hot, so I used one and dropped my NB temp 15C I appreciate the discussion

-

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

Hey that's cool. I better post some pics of them actually working. I had to "borrow" the clear acrylic top from my other PC, but then I was able to film the inside with smoke going through. I can only supply a small amount of smoke at once. But this is what the flow looks like all across the inside: I will try to get more like this. -

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

Today I opened the other side up to upgrade the lower fan to a 2000 RPM, this is much better with the bus, I think I will get another 2000, it runs super quiet and about 60cfm at 1500rpm. And a somewhat decent shot of the DVI connection and USB port. I tried to go with a 1 foot DVI cable, but it was about 1 inch too short. So it has a 3 foot DVI cable. -

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

The MB is a Gigabyte GA-8I945P-G running my Pentium 805D Dell never wrote me back about what they found, It was an engineer from the thermal server division who contacted me. It was right about the time thay had a financial issue, about May. Most companies I try to work with to get what will work best for thier application, I have a few different choices besides the sizes. Different cell sizes and thicknesses. I was quite surprized how many industrial applications 120mm fans have. Here is a pic of the 10 video boards from the CAT scanners, this is a design guide from Coolit for fan placement: Coolit makes thermal CFD estimates. Coolit thermal image applications -

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

I knew the LCD/PC would be hot, and the pixels can get damaged from extra heat, and my buddy kept telling me I was going to burn this thing up.. well, besides not wanting to have it burn up, I was hell bent to prove this guy wrong. But instead of getting on Tom's Hardware and reading what the latest best fan of the week was, I started reading about how to move air efficiently. It did not take long to find the wind tunnel research for dummies... (you know minus all the math) This is the highest study of fluid dynamics. And the more I read the more it made sense to apply to what I was doing. Reynold numbers and all the math I cannot calculate, but It seems to have proven very effective for seperating the hardware heat and cooling each one. Another great question, no one has asked me how it came about. Within weeks of opening the webstore I had orders from Dell, Analogic, several universities and such. Analogic used them on CAT scanners in the rotating gantry that has several video boards very tightly packed, they said they could not believe the performance increase. My other 2 PC's have honeycombs mated to the fans. These have been running for months, the biggest benefit I have noticed besides lower heat is the air moves so fast past the chipset and MB dust does not build up. Here is a pic of the one running on my blue PC: -

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

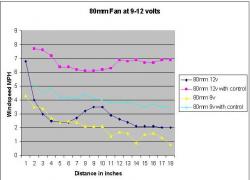

Well as much as I tried to read about it, "Almost all the knowledge acquired about diffusers is empirical.", so once I made one it was time to test it, and it has impressed me quite a bit since then. The purpose is really to maximize the input profile. With an open orifice, air takes the easiest path. With the honeycomb cells, all of a sudden the easiest path is restricted at that "easy" cell, so the rest of the cells more evenly distribute the force. So it is for ventilation but like wind tunnels application, is ensures consistency and uniformity. A diffuser on the other end was planned at first, to speed back up the airflow, but it is not really needed for this application. My next case I want to build with 1 fan and a few honeycombs to see if I can pull it off. Here is much more info about diffusers: wide angle diffuser Great questions by the way! This application of honeycomb is for the fanless input, but mated directly to the fan here I tracked out the airflow profile with an anemometer. -

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

You do mean on your PC radiator right? I have had people order parts for their automobiles. Especially Mass Airflow Sensors. If your fan is connected directly to the radiator it might not help much. But then again the honeycomb connected with the 1/4 inch spacing toward the fan you get a good flow in the center dead spot, so it might work well. If you want to PM me your address I will send you one and then you can give me a review for radiators, how does that sound? I have not tested them much on radiators. "The wide angle diffuser makes the flow speed decrease and the pressure rise. The recovery of pressure from kinetic energy reduces the power needed to drive the tunnel (airflow). " diffusers To my best understanding for the diffuser, it takes energy/work to get the air into the diffuser opening and expanded to the larger size. This comes from the fan, but as the air starts it journey through the rest of the system, that energy is not lost but captured by the settling chamber. The vanes ensure that the 120mm area gets filled evenly. Heat cannot to pass through 200 layers of air that is traveling straight between these two sets of hardware: PC/Monitor. -

Battleground Europe Theme Case

saxxon replied to saxxon's topic in Cases, Power Supplies and Modding

I got a few shots of some decent looking screens: And this one I made to mess with my friend Barry who said many times last december-janurary "your gonna burn that thing up" And I modified a screen to look as though there is critters living in my box. And ever since I started modding PC's I have wanted a box with this screen on the case, and now I do I made another diffuser for the lower portion. This cut my Reynolds number in half per diffuser, but the PSU and video card need their own supply. I forgot how much work I put into this little part until I had to copy it. 12 triangular pieces ready to go, it uses only standoffs on 4 of the vanes, unlike the force the NASA one contends with, 5MPH will be about the max this intake ever sees. Making something can be a challenge, copying it can be much more difficult. And I had to make another hole in the side panel, I attempted to cut this plexi without any masking tape on it, it just glued itself right back together without tack paper, so after a few passes I just put masking tape on and it cut like I was used too. And my scroll saw cuts anything but straight. So on edges I use the hand file to get straight and smooth. But for circles I have used sandpaper around something round and coned, in this case a drinking glass. For aluminum and plexi circles I have just used this technique and turned it until it's a perfect circle. Since I had the side off I took a few more close up's of how the monitor sits and the hardware from this side. And a close up of the keyboard area, you can see it is a pretty tight fit for everything that is there. When I first got my Viewsonic 20.1 inch I was putting the keyboard on the LCD stand (kinda) and it seemed pretty tucked out of the way, this is how I really got the idea to stick the keyboard in this thing. Since the drives were going to be facing me anyway. I also added a deflector to the outputs of each of the honeycombs. Once the air has been straightened it is very easy to control. One is aimed at the video card fan input and one deflects towards the monitor. The new right side: Then I run lots of tests with the handheld anemometer to check flowrates and pattens. And smoke testing also, I cannot get a good photo of smoke going through the dark plexi yet, but it is impressive. Natural smoke goes in leasurly and kind of mills around to find the fans. Through these 2 diffuser/straighteners it is all business, the trails get in, and get out quickly. And smoke crossing the entire input diffuser you can see it hits the monitor entire back panel (great to add active cooling where it was passive), and many seperation layers in between so they don't share heat. And what really surprized me was the airflow past the CPU. I bet if I had a straight fin heatsink instead of the spiral one, I could 86 the CPU fan. I am getting 2.1MHP flow past the CPU, not much less than passes through the heatsink with the low RPM stock fan. That was with the turbine 1000 fans. Today I got the Extreme Turbine2000: And they seem much more controllable on a bus, here I connected them to my blue PC bus. The lowest speed is about where the 1000's topped off. Extreme, I liked the sound of that. I just need to remove the manufacturers stickers, which I have done with all the parts. It looks like a stock car if you leave all the stickers on. I think my fascination with acrylic cases is being able to test them with smoke. The pink Gucci PC I made I spent hours messing with the fans, only to see they didn't really do much to help cool the P4 that it was running. This pic you can clearly see how the monitor is mounted, the black and silver ring are still attached. Compare with the stock monitor. Well that is pretty much it for the worklog. I have tons more pics but plenty were out of focus. And some are not much different than you see, if anyone wants a close up of something let me know. I want to thank EM3Bilko also, he has been very supportive and commented on my build many times. :thumbs-up: And thanks to everyone who took the time to read this and took interest in my work.